Modern engines are built for efficiency, performance, and lower emissions. To achieve this, they rely on precise fuel delivery systems that ensure the right amount of fuel reaches the combustion chamber at the right time. At the center of this process is the high pressure fuel pump, a crucial component in both gasoline direct injection and diesel engines. Without it, the engine cannot generate the pressure needed to atomize fuel correctly, leading to poor performance and potential engine damage.

This guide explores everything you need to know about the high pressure fuel pump — what it is, how it works, its components, common problems, maintenance practices, and its role in today’s advanced vehicles. By the end, you’ll understand why this pump is so important and how proper care can help keep your engine running smoothly.

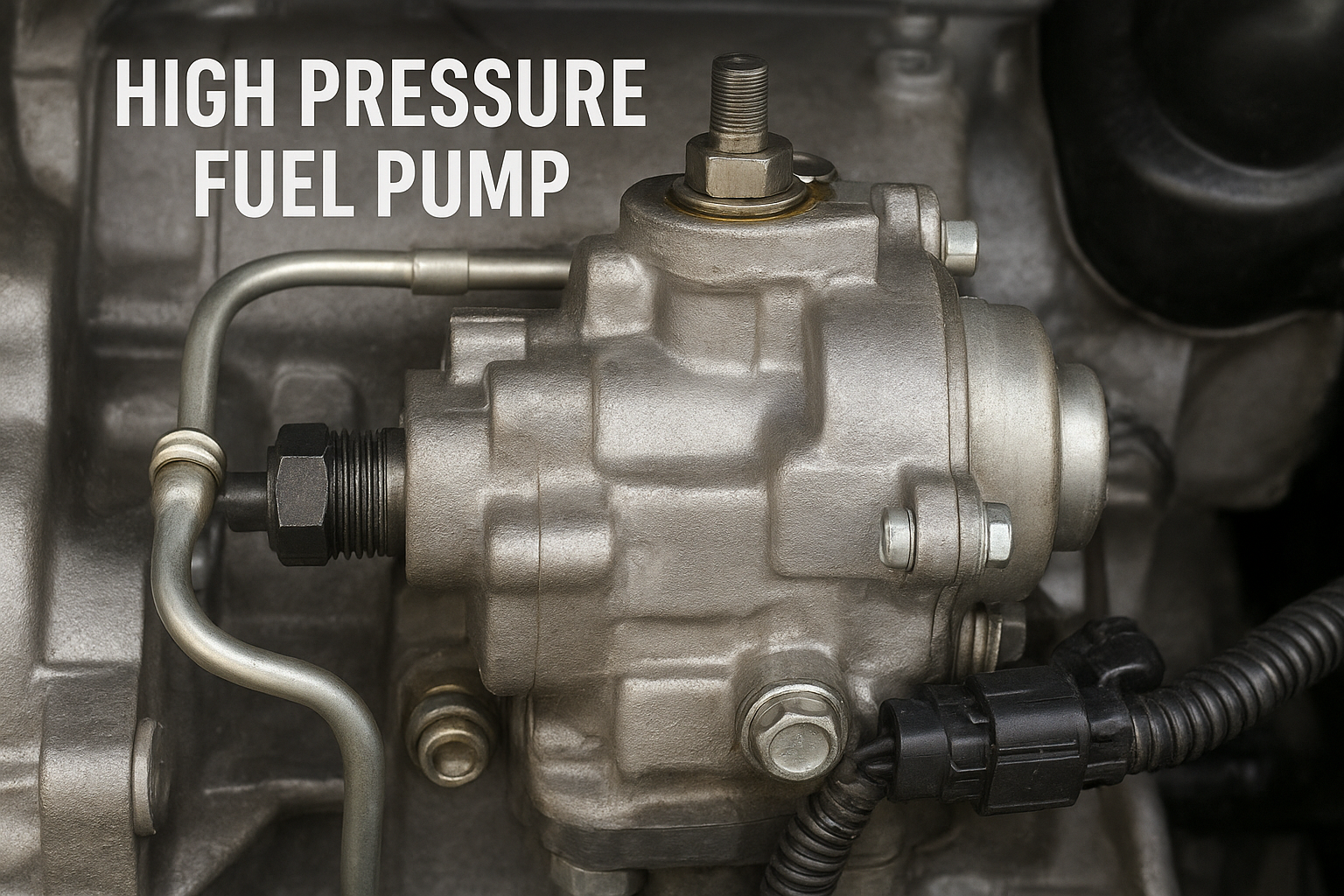

What Is a High Pressure Fuel Pump?

A high pressure fuel pump is a mechanical or electrically driven pump that delivers fuel at extremely high pressure to the fuel injectors. Unlike a standard fuel pump, which only transfers fuel from the tank to the engine at a relatively low pressure, this pump raises the pressure to a level where the injectors can spray a fine mist of fuel directly into the combustion chamber.

In gasoline direct injection (GDI) systems, the pump can deliver fuel at pressures exceeding 2,000 psi, while in diesel engines the pressure can be many times higher. This difference makes the high pressure fuel pump a specialized and essential part of modern vehicles. It ensures that combustion is efficient, controlled, and powerful, while keeping fuel consumption and emissions in check.

In simple terms, if a regular fuel pump moves fuel, the high pressure fuel pump prepares it for precision injection.

How a High Pressure Fuel Pump Works?

The working principle of a high pressure fuel pump is straightforward but highly precise. Fuel first leaves the tank with the help of a low-pressure pump. This fuel reaches the high pressure fuel pump, which compresses it to the extreme pressures needed for direct injection. The pump is usually driven by the engine’s camshaft or a dedicated electric motor, which provides the mechanical energy required to generate pressure.

Once pressurized, the fuel moves through fuel lines to the injectors. At this stage, the injectors spray the fuel as a fine mist directly into the combustion chamber. The atomization process allows the fuel to mix evenly with air, ensuring efficient combustion.

This system differs from older port-injection systems where fuel was sprayed into the intake manifold at lower pressure. With direct injection and a high pressure fuel pump, fuel delivery is more accurate, resulting in better power, fuel economy, and lower emissions.

Without a properly functioning high pressure fuel pump, the injectors cannot deliver fuel correctly, which means the engine will struggle to run efficiently — or may not run at all.

Key Components of a High Pressure Fuel Pump

Although designs vary between manufacturers, most high pressure fuel pumps share a few common parts:

- Housing: The main body of the pump that contains all moving parts and maintains durability under high pressure.

- Plunger or Piston: Driven by the camshaft or motor, it compresses the fuel to extremely high pressure.

- Inlet and Outlet Valves: These control the flow of fuel into and out of the pump. The inlet allows fuel from the tank, while the outlet delivers compressed fuel to the injectors.

- Seals and Springs: Essential for maintaining pressure and preventing leaks.

- Control Module or Solenoid: In modern systems, an electronic control system regulates how much fuel is pressurized, adjusting to engine demands.

Each component plays a critical role, and failure in even one part can affect the entire fuel delivery system.

Common Symptoms of a Failing High Pressure Fuel Pump

When a high pressure fuel pump starts to fail, the engine often provides clear warning signs. Drivers may notice one or more of the following:

- Difficulty starting the engine: Low fuel pressure makes ignition harder.

- Loss of power: Acceleration may feel sluggish, especially at higher speeds.

- Engine misfires: Uneven fuel delivery causes irregular combustion.

- Check engine light: Modern cars detect irregular pressure and trigger a warning.

- Unusual noises: A failing pump can produce ticking or whining sounds.

- Reduced fuel efficiency: Poor atomization leads to wasted fuel.

Ignoring these symptoms can lead to more severe damage, not only to the pump but also to injectors, pistons, and even the catalytic converter.

Causes of High Pressure Fuel Pump Problems

Several factors can lead to the failure of a high pressure fuel pump:

- Fuel contamination: Dirt, debris, or water in fuel can damage delicate components.

- Poor lubrication: Many pumps rely on fuel itself for lubrication, so low-quality or insufficient fuel causes wear.

- Excessive heat: Continuous exposure to high temperatures can reduce efficiency and weaken seals.

- Normal wear and tear: Like any mechanical part, the pump has a limited lifespan.

- Electrical issues: In pumps controlled electronically, wiring faults or module failures can disrupt operation.

Understanding these causes helps drivers and mechanics prevent damage before it becomes critical.

Maintenance Tips to Extend Pump Life

Although the high pressure fuel pump is built to be durable, proper care extends its life significantly. Using clean, high-quality fuel is the first and most important step. Regular fuel filter changes are also essential, as filters block debris before it can damage the pump.

Keeping the fuel tank above a quarter full helps prevent the pump from running dry, which could reduce lubrication. Periodic inspections by a mechanic allow early detection of leaks, pressure inconsistencies, or unusual noises.

In diesel engines, it is especially important to use the correct fuel additives when recommended, as this improves lubrication and prevents moisture buildup.

With these simple practices, drivers can prevent premature wear and avoid costly repairs.

Repair or Replacement: What to Expect

When a high pressure fuel pump fails, mechanics usually test pressure levels before deciding on repair or replacement. Minor issues such as seal leaks or electronic faults may be repairable, but in most cases, full replacement is recommended.

Replacing the pump is not a simple job. It involves working with pressurized fuel systems, which require safety precautions and specialized tools. Because of the complexity, replacement costs can be significant, depending on the vehicle type. However, a properly functioning pump restores performance, efficiency, and reliability.

High Pressure Fuel Pump in Modern Vehicles

In today’s vehicles, the high pressure fuel pump is more important than ever. Gasoline direct injection engines rely on them to deliver power while meeting strict emissions standards. Diesel engines, known for high torque and efficiency, would not function without extremely high fuel pressures.

As automotive technology continues to evolve, manufacturers are designing more advanced pumps with better durability and efficiency. Some hybrid systems even combine electric assistance with mechanical drive to improve performance and reduce wear.

In short, the high pressure fuel pump has become a cornerstone of modern engine design, bridging the gap between performance and environmental responsibility.

Conclusion

The high pressure fuel pump is not just another component in the engine bay — it is the heart of the fuel delivery system in modern vehicles. By compressing fuel to the necessary pressure for direct injection, it enables clean, efficient, and powerful combustion.

Understanding how the pump works, recognizing early signs of failure, and following basic maintenance practices can save drivers from costly breakdowns and extend the life of their engine. Whether in gasoline direct injection or diesel engines, the high pressure fuel pump remains an essential technology for today’s performance, efficiency, and reliability standards.

Taking care of this vital part ensures that your engine delivers what it was designed for — smooth, dependable, and efficient driving.

My name is Mustafa, and I have been blogging for over 5 years. I am passionate about sharing complete, accurate, and helpful information with my readers. Along with managing content on The Matcha Read, I also contribute blog posts to premium websites. My goal is to provide valuable insights in a clear and easy-to-understand way, so every reader walks away with useful knowledge.